Shiplap Vs Drywall Cost – Comparing Better Wall And Ceiling Coverings

This article made possible thanks to sponsors and viewers like you.

Buy TicketsListen up, folks, this ain’t no ordinary home design debate we’re having – this is about the legendary face-off between the timeless charm of shiplap and the modern sleekness of drywall. Now, there are loads of folks out there yapping about how shiplap’s 15 minutes of fame are about done.

But let me lay it down for you straight – they couldn’t be more wrong. Shiplap ain’t just some flash in the pan; it’s a rooted piece of architectural tradition, experiencing what you might call a renaissance, not just a fleeting moment in the sun.

Now, why is shiplap considered so damn iconic, you ask? Well, it’s simple.

That gorgeous wood grain hugging your walls, accented with that classic penny gap trim – it’s the stuff of interior design dreams. It’s like having the spirit of the forest right there in your living room, wrapping you in warmth and character. And if we’re talking turkey, it won’t have you breaking the bank compared to its contemporary, drywall.

Ah, drywall – the king of the modern castle with its impeccably smooth surface, a pristine blank canvas that’s become almost too perfect with the advancements in construction materials. Sure, any house can be slapped together with drywall to achieve that flawless look so many crave. But let’s not kid ourselves; for some, the uniformity of drywall feels about as inviting as a stint in Alcatraz. And me? I can appreciate the occasional sheetrock scenery, but an entire crib decked out in nothing but drywall is a one-way ticket to Dullsville.

Imagine, if you will, stripping a house of all its shiplap, tile, hardwood, you name it, and replacing it all with cold, lifeless concrete. Congratulations, you’ve just built yourself a cozy little penitentiary.

But let’s get back to the heart of the matter – wood, with its innate capacity to inject a dose of warmth and soul into any space, whether we’re talking sleek, modern aesthetics or timeless, traditional vibes. And shiplap? It’s the heavyweight champion of that arena. We ain’t talking about some fleeting trend here; painted or not, shiplap is the definitive classic, a staple of design that refuses to bow out to the whims of passing fashions.

So, when you stand at the crossroads of choosing between shiplap and drywall, remember you’re not just deciding on wall coverings. You’re deciding between embracing a piece of enduring charm, a link to architectural heritage, and settling for a canvas that, while smooth, may leave your space feeling a tad impersonal. Shiplap isn’t just surviving; it’s thriving, evolving, and proving time and time again that true style is timeless, not trendy.

Shiplap vs. drywall weight

Take your standard-issue drywall, about as common as dirt in building projects, but this sucker packs a punch with a 4×8 foot sheet clocking in at a heavyweight 47 pounds if we’re talking the ½ inch variety. Oh, you think that’s heavy? Lace up your gloves for the 5/8 inch drywall that ramps the ante up to a back-breaking 70 pounds per sheet. That’s the kind of weight that’ll make you wish you skipped arm day.

Now, let’s waltz over to the lightweight contender in this bout – shiplap. This slick, stylish option is like the featherweight champion of wall coverings. A standard 1×6 foot profile at 8 feet long barely tips the scales, coming in at just under 10 pounds. That’s right, this isn’t even a sweat for Kenny Powers.

So, why does this weigh-in matter? Because, my friends, it’s all about how much you’re willing to hustle when it’s time to throw down with installation. Drywall? That’s like going ten rounds with a heavyweight on your back, especially when you’re talking about decking out ceilings. It’s you and a buddy, if you’re lucky, trying not to get KO’d by a 70-pound slab of wall.

But shiplap? Oh, baby, that’s a solo dance. You can jive with that all day by yourself, sliding those lightweight, handsome strips up on your walls or ceilings without breaking a sweat. It’s like your wall is getting dressed in its Sunday best, easy and breezy.

Pick shiplap, and you’re floating like a butterfly; pick drywall, and… well, I hope you’ve been hitting the gym or hiring out the work.

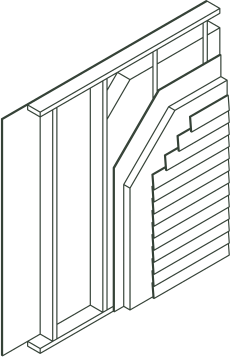

Shiplap vs. drywall installation

First off, when we’re talking about throwing up drywall on those walls there are no special tools required. It’s just you, the drywall, and your ambition. But when you’re aiming higher and looking to cover that ceiling, well, that’s when you need to bring in the big guns — scaffolding or a drywall lift. And if you’re dealing with ceilings that are touching the skies, then hell, you might even consider a scissor lift. Because, let me tell you, gravity will work against you.

Now, shifting gears to shiplap – it’s just as easy yet, requires a few more tools like an brad nailer and/or an air compressor if you opt for a non-electric nailer. You’ll definitely want to get your hands on a clamp or a hand pull to deal with any boards that decided they wanted to be a wave instead of a straight line, but that’s about it.

Here’s where the magic happens with shiplap: if you’re working solo, you can still knock it out of the park. Just take a piece of wood, about 5 feet or so, screw it into your starting strip of shiplap and let it jut out towards the part of the ceiling you haven’t gotten to yet. Then, when you add the next player to the lineup, slide it underneath that resting board, and boom, you’ve got support. Climb your ladder, get that piece secured, and then waltz down to where you’ve got your supporting wood. Easy peasy.

But, and there’s always a “but,” installing shiplap is like being in the bottom of the ninth with two outs and bases loaded. It’s slower, much like trying to steal home plate on a bunt. With drywall, you slap up a big ol’ sheet, and you’re rounding the bases. Shiplap, though, you’re inch by inch, board by board, and every piece has to be measured and cut, each one demanding its moment in the spotlight.

So, if I were to put a number on it, I’d say shiplap installation is draggin’ your feet 4-8 times slower compared to putting up drywall.

Airtightness

No matter how fancy you get with it, be it your regular ole shiplap or the fancy tongue and groove kind that nestles together tighter than a miser’s fist, you’re still gonna have air whispering through those boards like they’re passing secrets.

Why? ‘Cause wood, my friends, is alive. Well, not “alive” alive, but it breathes, expands, contracts like a heavyweight champ stretching before a big fight. And that dance it does? It leaves tiny little gaps, minuscule hidey-holes between each board where the air’s gonna make a break for it.

Now hold your horses, ’cause when we’re jabbering about the inside walls, it’s no big whoop. But slap those suckers on the outside or up against the ceiling, and buddy, you’re playing a whole different ball game. We’re talking about wanting those parts tighter than Kenny Powers’ fastball.

If you’re gutting the place, tearing it down to the bones, here’s a pro tip straight from the Powers’ playbook: slap in an intelligent membrane instead of drywall. Why? ‘Cause Kenny Powers didn’t become a superstar by doing things half-assed, that’s why. But if you’re dressing up pre-existing drywall with shiplap like it’s prom night, then heck, you’re golden. That drywall’s got your back like an air-blocking linebacker.

Drywall is the unsung hero here, folks. Big, solid, gapless – it’s the wall equivalent of a fortress. Tape up those seams, mud those corners, and bam – your casa is as airtight as my ego.

But let’s pump the brakes for a sec. Is a little air slipping through the cracks gonna bring about the apocalypse? Nah. Unless you’re hemorrhaging cash like it’s going out of style on your heating and cooling, in which case, maybe tighten up, Scrooge.

Now, here’s where I get real with y’all: shiplap with a brainy membrane? Some might call it overkill, but folks, I live for this stuff. And I’m not just talkin’ about keeping your house snug; I’m talking about waging war on those sneaky fiberglass insulation particles trying to crash your pad. Seal it tight, lock it down, and let’s keep the great outdoors, well, outdoors.

R-Value

First off, let’s talk about ½” Drywall. That stuff has got an R-value of 0.5 per inch. But bump it up a notch to 5/8” Drywall, and you’re looking at an R-value of 0.5625 per inch. Yeah, I know, not exactly earth-shattering, but every little bit helps when you’re battling Mother Nature.

Now, let’s switch gears to wood, specifically the type you might choose for some kick-ass shiplap walls. Most folks go for softwoods like pine because it’s as cheap as it gets and gives your place that rustic look that screams, “I’m both stylish and slightly dangerous.” This pine shiplap’s got an R-Value of around 1.41 per inch, which is like jumping from a moped to a motorcycle in terms of insulation power.

But hey, if you’re one of those high rollers who lights cigars with hundred dollar bills, you might opt for the heavyweight champs of the wood world – oak or maple. These hardwoods, while costing an arm and a leg, and maybe your firstborn, sit around an R-Value of 0.71 per inch. Less insulation bang for your buck, but who’s counting when you’re living large?

So, if we’re talking the heavyweight bout of insulating power, a 1×6” shiplap, clocking in at 0.75” inches thick, is strutting around with an R-Value of 1.0575. That’s like comparing a double shot of whiskey to a light beer when put side by side with Drywall.

But let’s not kid ourselves, even with shiplap flexing its insulating muscles, we’re still in the minor leagues compared to the major league players of R-21 insulation most new walls are packing. In the end, shiplap isn’t just about turning your space into a Pinterest-worthy sanctuary. It’s packing more a tiny bit more of an insulation punch than Drywall, making it not only a style statement but a smart choice for those looking to dial up their home’s cozy factor without going full-blown igloo. Will you notice the difference, however? I doubt it.

Thermal mass

So, here’s the deal with thermal mass or, as I like to call it, the heavyweight champion of maintaining your casa’s temperature. Imagine you’re laying down a foundation of solid bricks under the beaming sun all day long. Those bad boys soak up the heat, getting all warm and toasty, only to release it slowly back into your space as the moon takes the sky’s spotlight. On the flip side, think about a hefty paper book – it gets warm quick but loses that cozy vibe fast.

Now, you’re probably asking, “why do I care about thermal mass?” Here’s the kicker: leveraging this natural phenomenon, especially if you’re hitching a ride on the passive house train, means you’re banking free solar heat during the day that your home gently releases back to you as the outside cools down. And for the majority who aren’t living in some futuristic, self-sustaining eco-dome, thermal mass is your best friend when the modern world pulls the rug out from under you – say, when a blackout knocks out your heating. With a solid thermal mass game, your house isn’t turning into an oversized ice cube overnight; it’s staying toasty longer, giving you a fighting chance against the cold.

Let’s talk specifics. Gypsum, the rock star behind drywall, packs a heat capacity (J/K) of 1.09 and struts around with a density (kg/m3) of 1602. Wood, on the other hand, like the kind you’d find in a hipster’s shiplap-laden living room, is playing in the minor leagues with a heat capacity (J/K) of 0.42 and a density (kg/m3) of 550.

Breaking it down: Drywall is swinging twice as hard in the heat capacity department and tripling the density score against wood. That means if you’re looking to up your home’s thermal mass, doubling down on drywall is akin to drafting a first-round pick for your thermal lineup.

Fire resistance

Burn test time: We’re talking about throwing some chunks of shiplap and Drywall into an inferno and seeing which one decides to tango with the flames. Spoiler alert: shiplap is gonna dance like it’s the last night on earth, catching fire faster than rumors about me in my prime. Meanwhile, Drywall over there is just gonna get a mild sunburn on its paper face, barely flinching in the face of the blaze. The paper is what catches on fire, while the bonded gypsum core is what crumbles apart leading to failure.

Now, let’s break it down for you simpletons: if we’re talking about wanting to keep your crib from turning into a backyard barbecue, Drywall is like your knight in shining armor. Why? Because it’s basically made out of rocks. And even in my wildest nights, I’ve never seen a rock get lit. The cherry on top? You can mix some badass fiberglass strands into Drywall to make it even tougher against fire. Sure, its paper skin will char like my steaks on a bad grill day, but it doesn’t go up like a Christmas tree. It just sorta crumbles into a mess, putting an end to the show without taking the whole house down in a blaze of glory.

Now, for those of you thinking shiplap looks cool on your walls, hear me out. Most of those sheriff-like building codes won’t let shiplap near your fire-rated zones – I’m talking about that no-man’s land between your man cave (garage) and where you scarf down your midnight snacks (kitchen), or that mudroom where you dump your muddy kicks. Drywall is the law in these parts. But hey, if you’re really itching for that shiplap vibe, slap it over Drywall and boom, you’re both safe and stylish.

For all you decorators and style gurus putting up shiplap for that rustic or whatever look on your walls or ceilings – you’re cool as long as you’re not planning to barbecue indoors. And let’s face it, shiplap isn’t exactly a tinderbox; holding a flame to it doesn’t mean it’ll ignite like my fuse. It takes a hot minute. And if you’re into that exotic, hard-to-get stuff like IPE wood, which is tougher than a two-dollar steak – that stuff scoffs at flames for breakfast and won’t catch fire unless you’re really asking for it.

Construction mess

Tackling a drywall project is like stepping into the ring with a messy, unruly beast. You think you got it under control, then bam! You’re covered head to toe in dust and grime. You see, cutting into that sucker unleashes a storm cloud of dust. And don’t get me started on the Herculean task of sanding it down to achieve that baby-bottom smooth finish. It’s a dusty affair, no two ways about it, and no matter how many fancy gadgets or expert moves you pull, you can’t dodge the dust devil completely.

Now, let’s talk about that sneaky devil known as dry mud compound. This bad boy goes on slick but dries to a dusty nightmare, laying a fine coat over everything like a winter snow in the Rockies – including your floors, transforming them into a slip ‘n slide of despair. Sure, you can lay down floor coverings, tape up the seams, and perform a ritual dance in hopes of containing the splatter. But somehow, someway, that mud finds a way onto your shoes, trekking its way across your house like a determined explorer.

But here’s the plot twist, folks. Enter shiplap, the cool, calm, and collected cousin in the world of wall coverings. Cutting shiplap? Sure, it kicks up some dust, but it’s nothing compared to the drywall dust apocalypse. With a few smart moves like hooking up a bag or vacuum to your miter saw or taking the chop shop outdoors, you can pretty much tell that sawdust to kick rocks, keeping the mess to a minimum.

So, when it comes down to it, it’s like choosing between jumping into a mud wrestling match or lounging on a clean beach. Drywall is the mud pit, and shiplap? That’s your pristine sandy shore. Shiplap’s the way to go if you want to keep your sanity and your house clean.

Cutting

Now, drywall, she’s a straightforward companion in the world of renovation. Give her a good, sharp razor blade, and she’s ready to fit whatever space you’ve got in mind. Need to make room for those pesky outlet boxes? No sweat. A drywall knife in hand, and you’re carving out spaces with the precision of a seasoned chef. It’s a process so streamlined, it practically dances by in a swift, elegant ballet of efficiency.

But then, enter shiplap, the rugged, soulful type with a story to tell. This isn’t your quick-and-dirty kind of deal. No, shiplap asks for commitment, for a touch more finesse. You’ll be looking at your arsenal of tools – a circular saw or a miter saw to start. These aren’t just any tools; they’re your paintbrushes for creating that perfectly tailored space. And let’s not forget the small table saw, an essential for whittling down those boards to fit the nooks and crannies of your canvas.

But shiplap’s demands don’t end there. You’ll want a jigsaw by your side, ready to dive into the intricate ballet of cutting out outlet boxes and gracefully notching around whatever obstacles the walls throw your way. Shiplap doesn’t just bring a few more power tools into the equation; it invites a symphony of precision, planning, and passion.

So, what’s it gonna be? The swift, satisfying efficiency of drywall, or the deep, demanding craft of shiplap?

Durability

When it comes to durability, shiplap’s got drywall on the ropes, no contest. But, if you’re thinking of throwing in some fancy, high-dollar, abuse-resistant drywall, well, it might stand a chance. However, in the real world, where the Cornwell mansion and your humble abode sit, splurging on this kind of drywall is as rare as a unicorn sighting.

Put drywall in one corner – it might look tough but bump into it with your backpack or graze it with a door handle, and bam, it crumbles faster than my career pre-comeback. True, you can patch it up easy, but who wants to play nurse to their walls? Want to throw a punch or unleash a roundhouse kick? Drywall’s going down. Shiplap, though? That’s like punching a brick wall. Good luck to you.

Here’s the thing about shiplap – it’s like the veteran boxer who’s been through the worst and still stands tall. We’re talking hard, solid wood. But, if you decide to cheap out, go for that MDF stuff, “made wood,” you’re knocking down durability by a mile. It’s like filling your gloves with foam instead of lead. For the record, I do MDF in any build, not unless it’s for show and tells, like a mudroom that hardly sees action. For places that matter – living rooms, staircases – do it right. Fork out for the real wood.

Water and drywall? Forget about it. It’s like throwing your TV in the pool and expecting to catch the game afterward. Get it wet, and you’re ripping it out and starting over. MDF’s no champ either – introduce it to water, and it puffs up like a blowfish. Now, solid wood shiplap, that’s your water ninja. Rain or shine, it takes a beating and keeps on ticking. But let’s be clear – it’s tough, not invincible. Don’t go lining your shower with it.

You might think shiplap’s for those mountain or beach houses, something out of a lifestyle mag. But Brian Cornwell’s abode? It’s modern mountain – sleek, chic, but with that shiplap warmth that says, “Yeah, I’m successful, but I can still chop wood.” Shiplap, T&G, they’re not just materials; they’re a statement. Goes to show, whether your style is more yacht club or mountain retreat, there’s room for a little shiplap or drywall in your life. Timeless, just like the man himself.

The utility

Drywall’s got some serious mass to it, kind of like me in my prime. This means it’s gonna soak up sound like I soak up attention. If you’re looking to keep your neighbor’s annoying noise out or your own questionable music choices in, Drywall’s your go-to player. It’s about making your space a fortress of solitude—or chaos, depending on the day.

On the other flip of the coin, we’ve got Shiplap. Now, this contender might not be the heavyweight champion of soundproofing, but let me tell you, it’s got a secret weapon. Shiplap is like the reliable do-it-all-er, ready to hold onto whatever you throw its way—photos, shelves, or even that weird abstract art piece you drunkenly bid on at 3 AM.

With Shiplap, you don’t have to play a guessing game trying to find those elusive studs behind the walls every time you want to hang up your little league medals. Nah, you just screw right into the wood, and boom, you’re done. No fancy moves needed.

Now, let’s get real for a sec. Whether we’re talking Drywall or Shiplap, if you’re planning on mounting your 80-inch TV, where you’re gonna watch my highlight reels obviously, or that ridiculously heavy antique mirror that might be haunted, don’t mess around. Use anchors. I’m serious.

Regardless of which one you chose, you can always make both soundproof by using layers. Yes, drywall is more soundproof than shiplap, but with the right materials such as mass loaded vinyl behind the layers, you can achieve similar sound reducing results.

Because you asked about drywall vs shiplap: FAQ

Do you need Drywall behind the shiplap?

Yes, in fire-rated assemblies, such as separating the living areas from the garage, per local building codes. No, you do not need Drywall behind shiplap for all other home areas. If you are going with a 1×6″ (1″ thickness, which is actually 0.75″), then you can meet many local building code requirements for a wall covering.

If you are installing shiplap on exterior walls or ceilings, then it’s wise to install either a smart membrane (to stop air leakage) or install Drywall and use a lower level of finish. Tape and mud the seams and joints and then install shiplap over it.

Can you install shiplap over Drywall?

Yes, if you have Drywall installed, then removing it is no point. You may need some outlet and light switch box extensions, but those are cheap and simple to install. Keep the Drywall and let it serve as more thermal mass for your home or as the air barrier layer for your exterior walls or ceiling.

To install shiplap over Drywall, use longer finish or brad nails that can penetrate the Drywall and sink an inch into the wood studs.

Do you need glue to install shiplap?

No. Some folks recommend using glue over Drywall and installing shiplap over that. But glue only holds the wood shiplap to the paper face of the Drywall. There are a lot of tests out there that show that Drywall, when glued to the studs, relies on the strength of the paper facing and not the entire panel. The paper facing is weak and fails easily.

Go with a larger size finish or brad nail if you are worried about the strength of attachment.

How do you hide fasteners in shiplap?

Shoot your finish nails into the tongue, and you will have a nail-free finish that requires no wood filler. Keep in mind, though, that some boards can have a slight warp and may need a nail or two occasionally to get them to lay flat.

Alright, let’s dive deep into the crux of what every homeowner wrestles with when juxtaposing the charismatic charm of shiplap against the ubiquitous presence of Drywall. You’re teetering on the decision, caught between, “Do I splurge on that shiplap splendor?” or “Is it savvy to stick with good ol’ Drywall?” Let me break it down for you, from a perspective of someone who’s been in the trenches, nailing, hanging, and finishing more board feet of wall coverings than most.

When my hands went to work on our sanctuary, we played a game of mix and match – Drywall hugged the walls, while shiplap serenaded the ceilings. We flirted a bit with tongue and groove pine, giving those walls a personality boost, a departure from the monotone whispers of gypsum wallboard. But let’s park the aesthetics convo for a heartbeat and drill down into what really makes your wallet twitch – the cost.

At the time of hammering out this comparison:

– Drywall hovers around $14.68 for a 4×8′ sheet at ½” thickness, and its 5/8″ comrade at $16.98. We’re talking 32 square feet of potential wall or ceiling estate for roughly $0.46 per square foot.

– Swing over to shiplap, and a 1×6” 10’ pine piece winks at you for $9.97. Break that down, and you’re laying out $2.62 per square foot. Now, for those wood paneling projects, we’ve historically dropped about $1 or less per board foot. Shop around, my friends, because while Drywall treads a more consistent pricing path, shiplap prances around in price point fields that can vary widely.

So, what’s the wallet damage?

Drywall will nick you about $0.46 per square foot, whereas shiplap will dance around $2.62 per square foot. Simple math, shiplap invites a heavier financial flirtation, about 5.7 times more than its plastered counterpart, for the materials alone. Picture this: a 15×10′ wall could see you parting ways with around $69.60 in Drywall or a heftier $423 in shiplap.

But hold up, there’s more – fasteners and finishing touches:

– Fasteners for Drywall mostly play in the steel screw league, with collated strips making installations a breeze, if not by hand. Shiplap, however, prefers the elegance of brad or finish nails, with a nail gun as its dance partner.

– In terms of cost, we’re not splitting hairs here – drywall screws punch in a bit over $75 for a 5,000 box, brad nails curtsy at around $40. Though shiplap fasteners could cost you half of their drywall counterparts, we’re still not talking wallet-altering differences.

And let’s not waltz past the finishing phase:

– Drywall demands a bit more – taping mud, joint tape, corner bead – ballpark $20. Shiplap? A dab of wood filler at $10 for a sizable tub should have you covered.

A pivotal distinction – Drywall begs for primer before painting, while shiplap’s ready for its paint or stain debut without the priming prelude. Considering paint and stain run a similar financial race, shiplap can nudge you towards savings if you’re aiming for that natural wood finish – no paint, no problem.

Now, the heavy hitter – labor:

Drywall installation is cost-friendly, with finishers often working on a per-board wage, making larger jobs more economically palatable. Roughly speaking, expect to shell out $30-40 per hour for sheetrock mastery.

Shiplap? That’s another story. Carpenters are a rarer breed, with finish carpenters potentially clocking in at $60 per hour. Quality and locality can swing this pendulum, making your shiplap endeavors possibly rake in a 25-30% higher labor bill compared to Drywall.

But, let me toss in a curveball – from the trenches, shiplap installation is a smoother sail than Drywall. Personally? Give me shiplap any day over Drywall.

Wrapping this up:

Yes, shiplap leans on the pricier side for both materials and labor, but let’s not gloss over what you’re signing up for – a wall or ceiling finish that oozes character and warmth, a depart from the sterile embrace of perfect Drywall. Opting for shiplap is choosing to invest in a premium ambiance, a small price for a significant upgrade in your home’s narrative.

Alright, let’s dive into the real meat of this debate—beyond just scratching the surface of cost implications. When we’re contrasting Drywall and shiplap, we have to first talk about what kind of ballpark we’re playing in. And in the world of Drywall, thickness matters.

So, say we’re eyeing 5/8″ drywall—this sucker is the heavyweight champion in the realm of fire-rated barriers, like those betwixt your man cave garage and your plush living room. This heavyweight is packing more than just extra pounds over its ½” drywall sibling. In the universe of modern, swanky, custom cribs, you’re gonna see the 5/8″ Drywall flexing its muscles more often than not. It’s not just because some building code guru says so; this choice upgrades your fire combat readiness, cranks up your soundproofing to eleven between the rooms, and packs more thermal mass to keep your indoor climate more stable.

Plus, with this heavyweight, you’re not just getting a wall that stands tall; you’re getting one that’s less likely to bow down from the weight of time or your ambition. There’s talk in the streets that walking with the heavyweight champ might even make the insurance folks give you a nod on your premiums, although, between you and me, I haven’t shaken hands on that deal yet.

Now, if we’re talking dollars and cents, ’cause let’s face it, that’s where the rubber meets the road. To thick up your new castle with 5/8″ Drywall over the lean ½” is gonna set you back about a grand more for a pad of average stature. And if you’re asking me, that’s like deciding if you want the engine in your race car to actually start when you hit the ignition—if you’re putting in walls, go for the upgrade, baby.

But hang tight, we’re just scratching the surface here. Coming up, we’re gonna tear deeper into this, ’cause knowing the difference—it ain’t just essential, it’s what separates the architecture champs from the chumps.

No paid eBooks, courses, blocked content walls, memberships, or other pay-to-access nonsense. The Materials Magazine was built to educate + support the next generation; it’s forever free.